The Lubricant in a Chain or Gear Coupling Should Be Changed UPDATED

The Lubricant in a Chain or Gear Coupling Should Be Changed

In an platonic world, multiple components could be produced in a single piece, or coupled and installed in perfect alignment. Yet, in the real world, split components must be brought together and connected onsite. Couplings are required to transmit rotational forces (torque) between two lengths of shaft, and despite the most rigorous attempts, alignment is never perfect.

To maximize the life of components such every bit bearings and shafts, flexibility must exist congenital in to absorb the residual misalignment that remains after all possible adjustments are fabricated. Proper lubrication of couplings is critical to their performance.

Misalignment

Misalignment tin occur as either an offset or as an angular displacement on two of the possible three axes (Figure 1). The third axis, in the longitudinal management, is non normally measured, though errors in this management can result in constant excessive thrust loads in a system.

Figure 1. Types of Misalignment

For major installations, such equally large compressors, wire alignment methods are used. Smaller applications accept traditionally used rim and face dial indicator readings to quantify and correct misalignment, though optical laser indicators are apace gaining in popularity due to their ease of use and accuracy.

In pace-setting maintenance organizations, efforts are also fabricated to compensate for thermal growth that occurs in equipment during operation. All materials (except water) expand a small corporeality when heated, the amount by which they do so is governed by the textile's coefficient of thermal expansion and the degree to which it is heated. A machine that is brought into alignment at ambient temperature will pitter-patter into a position of misalignment as the machinery materials climb or fall to operating temperature.

Attempts are made to preheat or cool equipment to normal operating conditions before performing alignment checks. Alternatively, calculations of predictable thermal growth can be used to intentionally misalign the drive train at ambient temperature so that it may grow into alignment.

Whatever precautions are taken to make alignments as precise as possible some amount of residual misalignment will inevitably remain. Misalignment forces rigid machine components such as shafts to deflect in guild to effectively become aligned.

This deflection stresses the components, causes vibrations, and distributes higher and uneven loads on the structures that support these elements, such as bearings. These stresses waste matter energy and tin dramatically reduce equipment life and reliability.

Designed properly, couplings tin absorb misalignment forces then that more expensive, critical and sensitive components may be saved. While rotating shafts appear sturdy, the bearings which support them are some of the nearly sensitive precision components in the drive train.

Types of Couplings

Coupling designs may be divided into four principal categories, each having several specific designs. Solid and magnetic couplings do not require lubrication, but are included here for abyss. Solid couplings are fundamentally rigid structures that do not compensate for misalignment, but do let two shafts to exist joined for the purpose of transmitting torque.

Bolted hubs keyed onto shafts are a common instance of a machine with magnetic couplings. Magnetic couplings let shafts not in direct contact to be driven together using powerful permanent or electrical magnets. A sealless magnetic bulldoze pump is a common example.

There are some conventional applications that could be fitted with a stand-lone magnetic coupling using this same principle and ultra-powerful (and expensive) permanent magnets.

Other coupling types are flexible couplings and fluid couplings. Many flexible couplings employ fixed position flexible metallic, rubber or plastic elements, such as discs or bushings, that rotate with the shafts and absorb misalignment. Designs of this type do not crave lubrication.

Others such as geared, chain, grid and universal joints exercise require lubrication for proper performance and longevity. Fluid couplings include torque converters and torque multipliers every bit well as insufficiently unproblematic fluid couplings, which are couplings filled with lubricating fluids that rely on the fluid itself to transmit torque.

Flexible Couplings

Gear couplings (Figure 2) recoup for misalignment via the clearance betwixt gear teeth.

Figure 2. Gear Couplings

Shaft-mounted external gear teeth on both shafts mate with internal gear teeth on a housing that contains a lubricant. Other designs mountain external teeth on only i shaft, mating with internal teeth mounted to the other shaft.

Acceleration or deceleration can result in impacts betwixt gear teeth due to backfire from the clearance being taken up on opposite sides of gear teeth. Misalignment will result in sliding relative move across mating teeth every bit they pass through each revolution.

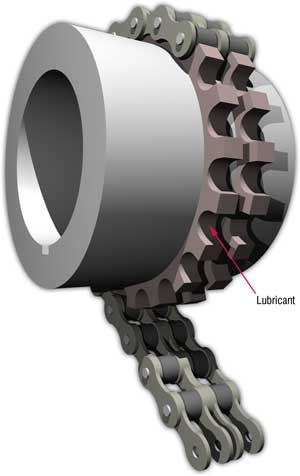

Chain couplings (Figure three) operate similarly to gear couplings. Sprockets on each shaft end are connected by a roller chain.

Figure 3. Chain Couplings

The clearance between its components besides as the clearance in mating the chain to the sprockets compensate for the misalignment. Loading is similar to that of geared couplings.

External grid couplings (Figure iv) employ a corrugated steel filigree that bends to compensate for loading induced by misalignment.

Figure 4. Grid Coupling

Grooved discs fastened to the ends of each shaft house the grid, which transmits torque betwixt them. Low aamplitude sliding motility develops between the filigree and grooves as the grid deforms under load, widening in some locations and narrowing in others over each revolution.

Universal joints are used for maximum allowable misalignment up to 20 to 30 degrees, depending upon the specific blueprint. They are used extensively for the drive shafts of vehicles to let the wheels to move with the suspension arrangement. Universal joints use a iv-spindled component chosen the spider to connect two shafts terminating in yokes or knuckles at right angles (Figure 5).

Figure 5. Universal Joint

Each of the four spider journals is supported by a bearing or bushing contained in ane of the knuckles, which allow articulation. In some cases, greater articulation can decrease wear rates by allowing more complete development of a lubricating motion picture.

Lubricants for Flexible Couplings

Both lubricating oils and greases can be selected to lubricate flexible couplings. Unless specifically noted by the coupling designer, couplings for the bulk of industrial components are grease lubricated. Coupling components are protected primarily by an oil film which bleeds from the grease thickener and seeps into the loading zone.

Lubricated flexible couplings require protection from the low aamplitude relative movement that develops between their components. Other concerns include centrifugal stress on the lubricant (particularly grease), which causes premature separation of the oil from the thickener, poor oil distribution inside the housing and oil leakage from the housing.

The motion's low amplitude, articulation speed, and tendency toward a sliding rather than rolling action inhibits the development of hydrodynamic (full-film) lubrication. Greases made with high-viscosity base oils, antiscuff (EP) and metal-wetting agents are recommended to overcome the purlieus (mixed film) conditions that oft exist in flexible couplings. High oil viscosity also slows the leakage rates.

Centrifugal forces in flexible couplings can exist extreme, condign greater as distance from the rotational axis is increased. Even moderately sized couplings can generate forces thousands of times greater than gravity (referred to equally Gs). Grease manufacturers place a loftier priority on formulations that resist premature separation of oil and thickener due to the high G forces.

Fluid Couplings

Fluid couplings transfer momentum from the input shaft to a fluid and then to the output shaft when transmitting torque. Misalignment is accommodated solely by clearances between the moving parts. The small clearances don't provide much room for error in alignment. However, it is possible to effectively compensate for daze loading and loftier torque starting loads, as in that location is no solid connection betwixt input and output shafts.

In fluid couplings, an impeller attached to the input shaft accelerates fluid inside the coupling as information technology spins, much like in a centrifugal pump. This fluid and then hits the vanes of the output shaft'south runner, transferring its momentum equally the runner accelerates. It volition advance until it approaches the speed of the input shaft, but will never actually reach it.

The difference in speed between the input and output shafts is known as slippage. Of course, frictional and gummy elevate must be overcome earlier the output shaft can rotate. The minimum input speed required for this condition is known equally the stall speed. Equipment with large static loads, such as a steam or gas turbine, would incorporate a fluid coupling to minimize the initial stress on the driving shaft.

Shock loads on the input side, such equally starting torque, are never created. The speed of the input shaft is never restrained. When the stall speed is exceeded, the output shaft will brainstorm to accelerate, just will practice and so at a constrained charge per unit due to its moment of inertia (resistance to athwart acceleration).

Slippage is created equally the runner accelerates to the speed of the input, dissipating backlog energy through viscous heat generation in the fluid. Output side shock loads volition be similarly dissipated, fifty-fifty if the output shaft should completely stall.

Torque converters and multipliers are special applications of fluid couplings that allow the input torque to exist modified earlier transmission. These designs operate fundamentally by the same principles, but are mechanically much more circuitous. A detailed word of these devices is outside the telescopic of this commodity.

Lubricants for Fluid Couplings

The dissipation of energy that makes fluid couplings so tolerant of shock loading creates the potential for rapid and extreme increases in fluid temperature. The energy dissipated during stall and skid is converted to oestrus through the mucilaginous shearing of the fluid (fluid internal friction).

In farthermost applications, such as a torque converter in an automobile climbing a steep hill or pulling a heavy load, the fluid temperature can ascension substantially to a higher place the normal 200°F operating temperature in less than a minute.

Oxidation and thermal deposition resistance are important qualities of oil used for fluid couplings considering of the potential for desperate temperature increases. Similarly, a loftier viscosity index (6) is also useful to prevent severe decreases in operating viscosity at temperature spikes and excessively high operating viscosity at low temperature conditions.

Low viscosity fluids are ordinarily used in these applications to reduce the power lost to heat due to fluid friction. Fluid coupling viscosities may autumn between 2.five to 72 cSt at 40°C. For fluid couplings designed to operate at loftier temperatures, such as in automobile ATF applications, viscosity limits may be given at 100°C. Typical automotive ATF requirements would exist three to 7 cSt at 100°C.

These fluids must besides resist foaming due to the astringent agitation acquired by the impeller'south motion and its impact upon the runner vanes. Rust protective backdrop help preserve the coupling's metallic components. Hydrocarbon-based fluids are superior in this regard to other fluids, but their performance tin be further improved through rust inhibiting additives. Seal compatibility is also important for long-life usefulness.

Maintenance Recommendations

Acceptable life can be expected from any of these devices only if proper maintenance is performed. Lubricant levels and quality must be verified through periodic checks. Additional lubricant may need to be added to recoup for leakage, and periodically the lubricant must be flushed and inverse to remove harmful byproducts of lubricant breakdown, to replace oil-depleted grease or to refresh the additive population.

Gear couplings require perhaps the most maintenance. Typical relubrication intervals are six months to one year, depending upon application severity and experience.

All maintenance tasks must be performed with attending paid to contamination control. The sliding contact suffered by many couplings indicates that abrasive three-body clothing caused by particulate contamination could be particularly damaging. Improper removal of solvents used to clean couplings during inspections and flushing operations can lead to significant viscous thinning of the lubricant in operation, or detrimental reactions with grease-thickening materials.

All couplings will endure significantly better when the demands placed on them are reduced. Consider the first line of defence force to be a minimization of daze loading, including difficult starts and sudden load reversals. Sometimes operational demands make this impossible. The principal source of loading in coupling systems can exist controlled to a great extent, however. Proper alignment is considered a high-priority, precision maintenance functions.

Use vibration assay or thermography during operation to identify couplings that are not in alignment, as fifty-fifty the sturdiest foundations shift over time. Certainly, check for proper alignment whenever intrusive maintenance or repairs are performed on the coupled components.

References

Chevron UsA. Inc. Technical bulletin: "Application Department Couplings." August 1990.

Mobil Oil Corp. Technical publication: "Coupling Lubrication Service Guide." 1986.

DOWNLOAD HERE

The Lubricant in a Chain or Gear Coupling Should Be Changed UPDATED

Posted by: debrafecou1946.blogspot.com

Comments

Post a Comment